A range of high-precision Mineral Insulated Cabling systems for severe nuclear environments.

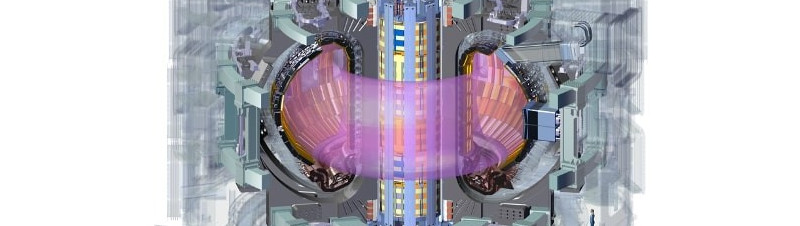

Thermocoax manufactures robust MI cables with intrinsic benefits for use in nuclear reactors. The advantage of the mineral cables is that they can withstand substantial stress and high temperatures. In addition, they provide highly stable performance over time. Both of these features make them uniquely suitable for use in extreme radiation settings such as nuclear islands.

Whether in low radiation settings or harsh environments, safety is paramount. Following the Fukushima nuclear power plant disaster, tighter regulations were introduced in the sector. And Thermocoax responded with new MI solutions to meet the new standards.

Designed and manufactured for the lifetime of a nuclear power plant, these MI cables are a total low-cost solution.

Mineral insulated cables for the nuclear sector

Thermocoax mineral insulated cabling solutions are ideal for applications in ex-core or in-core reactors. Suppliers of I&C systems to the nuclear industry will be interested in our transmission cabling systems and connectors.

Our innovative MI cables are developed to perform under the most severe conditions. Which is why they are often employed in nuclear islands. As required by changes to the regulations, the cabling system remains functional even in the event of an accident.

Highly stable and safety-compliant cabling systems

Thermocoax manufactures cabling that is compliant with all safety requirements in the nuclear industry for nuclear islands.

Transmission cabling systems

Our transmission cabling systems can be used for power, instrumentation and control solutions. They are suitable for low capacitance signal, high frequency signal with single and multiconductor systems. Precision manufacturing across their entire length means they are a perfect candidate for high radiation or high temperature environments.

Twisted conductors are available if required and the raw materials have a low cobalt content to prevent activation of the cable. Furthermore, Thermocoax transmission cabling does not need replacing for the lifetime of the NPP, making it a cost-effective solution.

Cabling system connectors

Thermocoax cabling system connectors are designed to withstand the radiation, pressure and temperatures of a design-basis accident. There are various solutions, according to their use in a range of nuclear settings – from low radiation to severe accident conditions. The state-of-the-art ceramic seals ensure long-term tightness and prevent outflow in a LOCA & post-LOCA situation.

Organic coated MI cabling systems

These MI cables are equipped with an outer sheath of extruded plastic, made with radiation-qualified organic materials. They also come with all the benefits of MI cables in terms of robustness. For installations requiring colour coding and/or electrical insulation of the metal sheath, these organic coated cables are the perfect solution.

Enhanced mechanical & electrical performance

Thermocoax MI cabling systems are safety-critical products designed for the lifetime of an NPP. They are low-cost solutions manufactured with the ALARA principle in mind.

Physical tests and digital simulations under normal and accident conditions ensure excellent functionality and stability under extremes of temperature, pressure and radiation.

Technical Data for MI cabling

Transmission cabling systems

- Unique electrical properties

- Cost-effective

- Multiple configurations

Cabling system connectors

- LOCA & post-LOCA resistant

- State-of-the-art ceramic seals

Organic coated MI cabling systems

- Radiation qualified organic material

- Plastic extrusion on metallic outer sheath

- Colour coding to facilitate routing

- Additional security layer

For more detailed information on Thermocoax MI cabling systems and our other products, please don’t hesitate to request a quote.